BREAKING: OptiMate is now available for CW 600

Thanks to significant advances in IoT, big data and machine learning, human-machine interfaces (HMI) have changed dramatically. In just a few decades we've witnessed the evolution from simple push buttons to interactive interfaces. And with Industry 4.0 increasingly gaining a foothold, more and greater advancements are to come, especially in the realm of packaging machines.

ACMA, a leading manufacturer of automatic packaging machines with nearly a hundred years of expertise in the industry, is at the forefront of innovation when it comes to HMI and its customer-centric approach puts the necessities of innovation of the clients at the center of its strategy. Developed by Coesia Digital and made available to the whole group, OptiMate is the latest breakthrough software in this regard —the perfect solution for improving your packaging machine's efficiency and productivity. Its distinctive approach truly makes life easier for the operator, especially when it comes to complex and advanced tasks.

OptiMate is a fundamental asset not only for controlling and monitoring the machine in a simple and intuitive manner, but also for production optimization and, consequently, due to its low material and energy consumption. Since the first application on the CW 800, ACMA has been using OptiMate to revolutionize its machine portfolio — including the Premium segment — and make it ready for Industry 4.0. In addition, ACMA offers the possibility of customizing the software according to customer requests, wisely managed by its dedicated team of experts.

What OptiMate is and how it can boost your productivity

OptiMate is a game-changing tool for manufacturing professionals in the packaging industry. Built upon the principles of user-centered design (UCD), ACMA's innovative web HMI, developed together with Coesia Digital, was optimized to meet the evolving customer needs according to three core tenets:

- Simpler is better

- Compatibility with most common PLC protocols in the market is key

- Being Industry 4.0-ready is essential

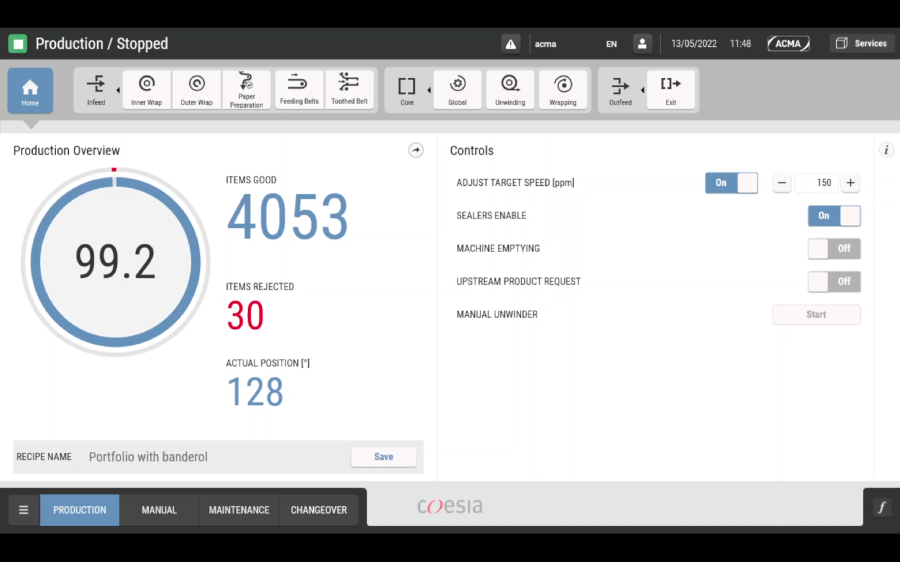

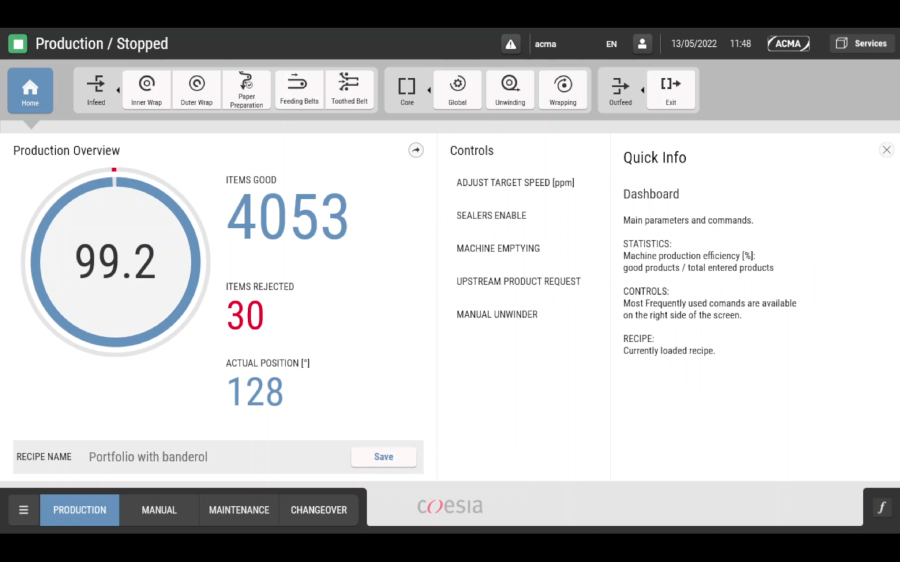

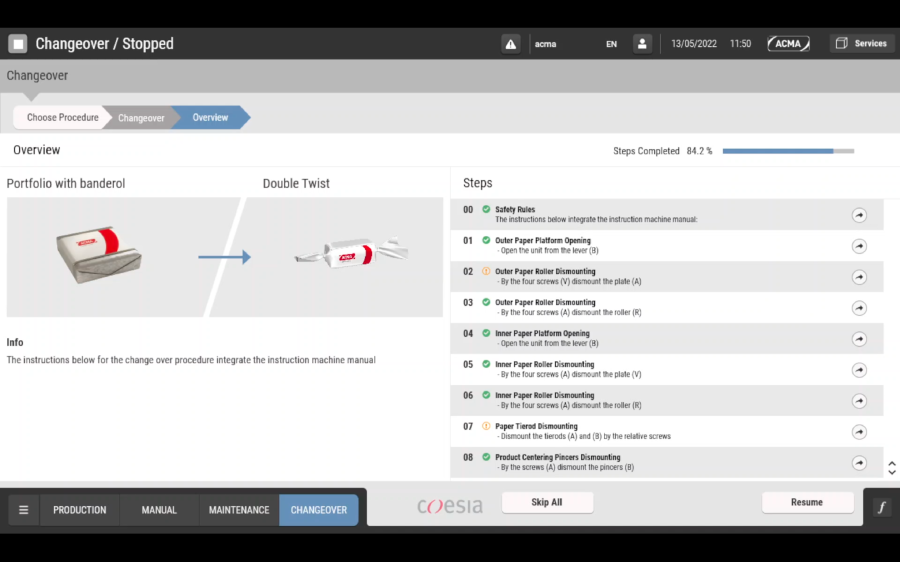

Not only does OptiMate boost the overall equipment effectiveness (OEE), it also makes it easier to diagnose problems with real-time data, providing troubleshooting assistance, format change support and actionable insights to the operator. Most notably, it gives the customer all key information at a glance — production data, technical documentation, performance analysis and main machine controls — encapsulated in a single, user-friendly dashboard.

With OptiMate, the operator's job couldn't get any easier. Unlike competitive solutions, the software provides only the relevant information for the task at hand, guiding the worker through their assignments. When powered by this solution, the machine works as a single point of access for the entire portfolio of ACMA's digital services, such as customer care, big data analytics, IoT as a service and machine learning algorithms. The system also alerts the customer about machine status, scheduled maintenance and alarms, enabling exportable reports and smart control, monitoring and navigation, both on-site and remotely.

Last but not least, OptiMate will be soon integrated with the Coesia Webshop, Coesia's online shop for spare parts, allowing the customer to surf through the entire Coesia catalog, compare prices, check availability and lead times and, most importantly, purchase spare parts directly from the machine interface — all with a single click.

Introducing OptiMate for CW 600

OptiMate is already available for numerous ACMA machines, including CW 800, HW 900, JW 700, CW 1005 and WMM. What’s more, it is also available with a proprietary Coesia panel, the hardware solution optimized for the Coesia Digital offer. Recently, ACMA has enabled OptiMate also on one of its most popular fold wrapping machines — the CW 600. With this model the software sees its masterpiece application and all its potentialities can be released to take the machine efficiency to the next level, as the packaging machine can manage many different wrapping styles and OptiMate is essential to support for the changeover.

The CW 600 is a multistyle wrapping machine for flat-base, preformed products with single- or double-wrapping materials. The machine stands out for its flexibility and high-quality wrapping, enabling up to six wrapping styles thanks to its modular design. The CW 600 also excels for its quick size changeover (up to a maximum of 30 minutes) and the impressive usability, easy maintenance and cleanability, featuring both right-hand and left-hand product out-flow solutions. The design is simple and very compact, with an integrated electrical cabinet, providing easy and direct access to all machine modules from the front.

The essential guide to OptiMate’s features for CW 600

With ACMA’s new web HMI, the CW 600 becomes intelligent — ready for Industry 4.0. This is particularly true if we consider the latest upgrades to OptiMate, implemented on this model via over-the-air (OTA) update.

Here is the complete list of the main features of OptiMate:

- Troubleshooting alarm list: thanks to this feature, the operator is provided with images and in-depth details over the issues in question.

- Quick info box: OptiMate now features a small info box on every page of the web application. The box is page-specific and summarizes the main functionalities of the product or part at hand.

- More informative exportable reports: with the latest upgrade, exportable reports now provide OEE data, sorted by production batch and production shift. In addition, OptiMate now gives a more detailed analysis of the production data, complete with the number of products that have already been manufactured, the number of scraps, the number of products that have been wrapped properly and so on. All reports are available in video format and can be downloaded on a USB key. The customer can also link the machine to a supervisor to enable data exchange.

- Top 10 alarms: it is now possible to view the top 10 alarms for a faster and better understanding of the problems related to the equipment.

- Quick and easy access to user manuals: the operator can now access the information directly from the panel via Adobe reader in full screen, enabling quicker and easier navigation.

- Better changeover support: both size and wrapping style changeover step-by-step procedures now come with image support and alerts in case the format change hasn't been properly completed.

- Better diagnostics: the backlog now shows a lot more data, including information about the power absorption of the motor, welder, oil temperature, complete overview of the I/Os connectivity, information about any ongoing variation of the process and, furthermore, data regarding predictive maintenance procedures, e.g. motor data, real-time status scan, etcetera.

The CW 600 is nothing short of a groundbreaking, cost-effective fold wrapping machine. OptiMate turns it into one of the best offers available on the market — a smart, user-friendly solution, powered by IoT.

If you want to experience the power of OptiMate on the CW 600, don't wait for it: get in touch today.