Revolutionizing Confectionery packaging: ACMA unveils the high-speed wrapper CW 1400

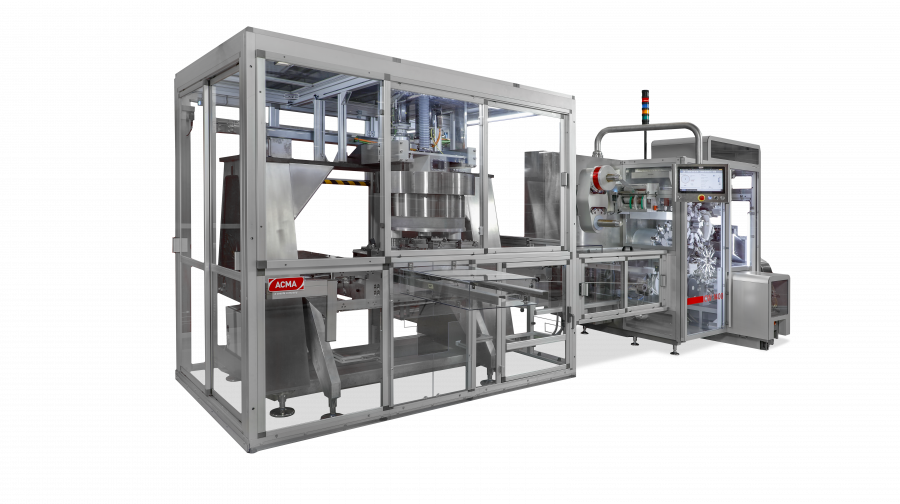

ACMA, a leader in packaging innovation, has unveiled its latest high-speed wrapping solution: the CW 1400. Designed for efficiency, precision, and gentle product handling, this cutting-edge machine sets a new benchmark in the confectionery industry.

With an impressive speed of up to 1.400 pieces per minute, the CW 1400 is engineered to wrap delicate products like chocolates, pralines, candies (jellies included), and éclairs with unparalleled accuracy. The machine supports double twist style for both flat and round products, as well as protected double twist for flat-base items, ensuring versatility for confectionery manufacturers.

The cantilevered design provides easy access for operations and maintenance, making it a highly user-friendly solution for high-speed confectionery production. Maintenance is simplified with a modular design, enabling quick servicing with minimal downtime. Enhanced digital capabilities allow predictive maintenance and real-time production monitoring, helping prevent unexpected operational issues. Additionally, the machine features a "No Product - No Wrapping" function, which minimizes material waste even at peak performance.

One remarkable feature of the CW 1400 is its delicate product handling capability, achieved through three continuous motion wrapping heads that maintain product integrity even at high speeds. Its high-accuracy product timing system, driven by brushless motors, optimizes efficiency. The machine's geared group motorization ensures perfect synchronization in every wrapping stage, allowing for seamless operation and the servo-driven unwinding and cutting system, along with a patented automatic splicer, ensures flawless wrapping material management.

The CW 1400 offers a range of optional features designed to enhance efficiency and ensure top-tier packaging performance. It can be equipped with a selective reject system for efficiency optimization, an additional fourth reel with single reject capabilities with a dedicated camera vision setup. This advanced solution guarantees 100% output quality control, provides statistical analysis of potential machine issues, and reduces waste during reel splicing.

To accommodate different product shapes, the CW 1400 ca be configured with different infeed systems, each delivering unique benefits. For spherical products, manufacturers can choose between the VL, an automated pick-up solution from counter molds with a compact, robot-free layout; or a patented hopper and disk infeed that allows machine compact footprint and widens its capabilities in terms of different product management, maximizing infeed efficiency and layout versatility.

For flat-base products, the option is the LCF, an automated timing belt system with a movable junction that ensures perfect product alignment closing potential gaps between products to deliver constant product flow and maximize performance and efficiency.

The launch of the CW 1400 underscores ACMA's commitment to deliver excellent packaging solutions that optimize speed, precision, and reliability. This latest innovation ensures manufacturers can meet high demand while maintaining product integrity and reducing waste.

For more details on our new CW 1400, contact us today.