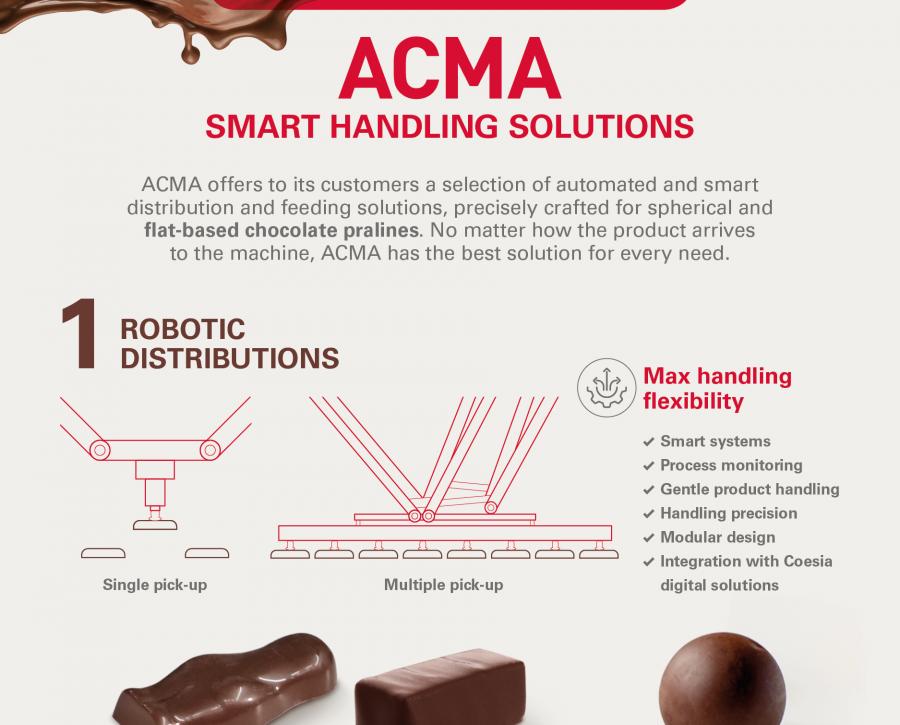

ACMA Smart Handling Solutions: robotic automations for chocolate pralines

ACMA infeed and distribution portfolio for Confectionery offers multiple automated solutions for managing flat and round products, from modular robotic distributions to order and orientate flat products, to compact infeeds to easily orientate flat chocolate pralines, to high-speed automated distributions for chocolate spheres. Moreover, all these products can be integrated with Coesia digital solutions.

Robotic Distribution provides two distinct pick-and-place systems. The first option can orient and align random products from a conveyor by directly connecting to a scanning camera that detects the product position. The second option is designed to handle products already in line, coming from a tray.

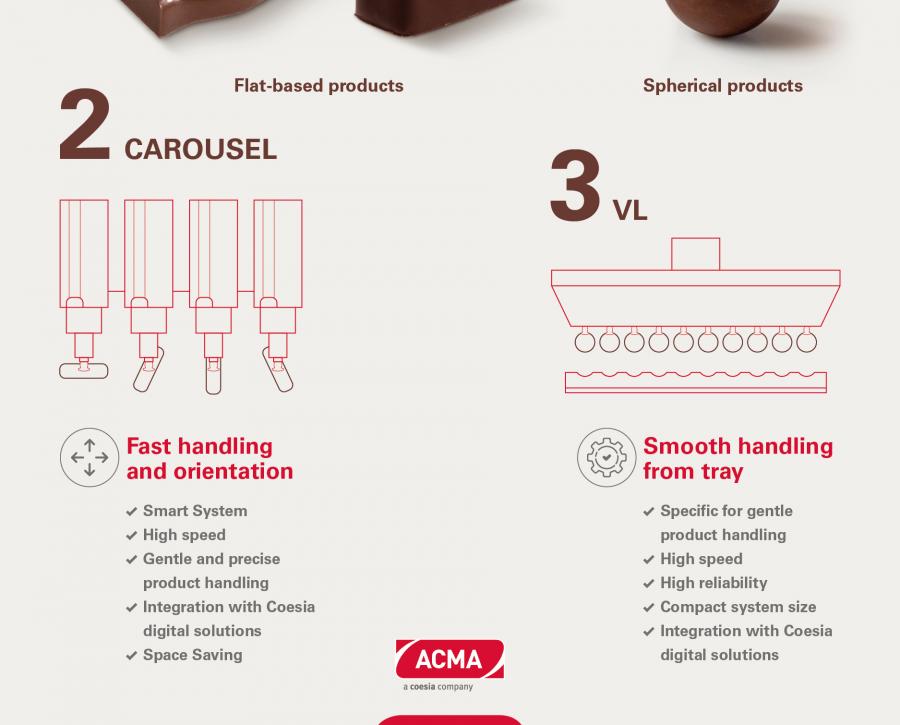

Carousel is an innovative patented smart infeed system designed for the CW 600, facilitating the orientation of flat-based chocolate pralines prior to the wrapping process. This compact solution, integrated with an advanced vision camera, offers cutting-edge performance even at high speeds, reaching up to 600 pieces per minute. With a focus on gentle product handling, the Carousel also ensures space and energy efficiency.

Tailored for the high-speed wrapping machine CW 1005, VL is a distribution engineered to handle spherical chocolate pralines from a tray, ensuring gentle product handling at high speeds. This solution is ideal for those with demanding production needs unwilling to compromise on quality, VL excels in speed, boasting high reliability and maintaining a compact system size.